With the development of science and technology, more and more new materials and new technologies are applied to the R&D and production stages of automobiles, so that automobiles can meet the requirements of light weight, low cost, intelligence, economy and reliability. For the use of new materials, ceramic PCB is one of the better materials, so where is it often used in automobiles?

1. Engine

Ceramic PCB can withstand high temperatures above 1000℃, which is beneficial for the development of new automotive applications. Nowadays, about 78% of the energy consumed in a car engine is in heat and heat transfer. In order to reduce this loss, the combustion chamber is insulated with a good thermal insulation ceramic material, and then the exhaust gas energy is recovered through the exhaust gas turbocharger and power turbine. Experiments have shown that this can increase thermal efficiency to 48% while reducing thermal energy loss.

2. Shock Absorber

The shock absorber of the limousine is an intelligent shock absober developed by integrating the positive piezoelectric effect, inverse piezoelectric effect and electrostrictive effect of the ceramic PCB.

3. Sensor

The requirements of automotive sensors are to be able to adapt to the harsh environment of the vehicle for a long time, but also to have the characteristics of light weight, good reusability, and wide output range. Ceramic PCB have the advantages of heat resistance, corrosion resistance, wear resistance and potential excellent electromagnetic and optical functions. In recent years, with the development of manufacturing technology, it can be fully utilized, and sensors made of ceramic PCB can meet the above requirements.

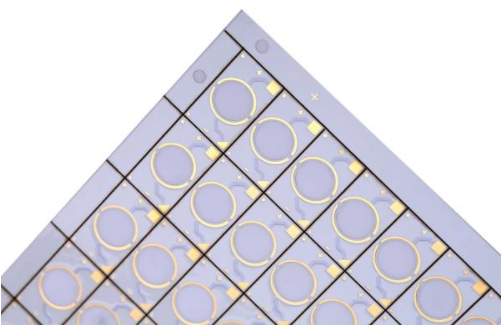

In summary, ceramic PCB has excellent comprehensive properties and is an important material in the automotive industry. It is more and more widely used in automobiles and is of great value to improve automobile performance and reduce fuel consumption. HoYoGo is an international, professional and reliable PCB manufacturer. At the same time, we also have experience in the production of single sided and multilayer ceramic PCB, high level automation and dedicated automotive production line, excellent and stable quality system. Among them, the PCB in the automotive field accounts for 45%.