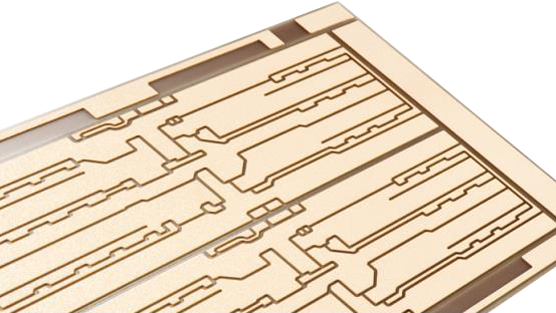

Ceramic PCB is to combine copper foil and ceramic substrate by bonding in a high temperature environment. In this way, the bonding force is strong, not only the copper foil will not fall off, but also the reliability is high, and various performances are still stable in the environment of high temperature and high humidity. So what are the materials of ceramic PCB? What are the reasons for using this material?

1. Aluminium Oxide (Al2O3)

Aluminium Oxide is a commonly used material in ceramic PCB, because it has better mechanical, thermal and electrical properties than other ceramic materials, good stability, and rich sources of raw materials, so it is suitable for a variety of technical manufacturing and different shapes. In addition, attention should be paid to the content of aluminum oxide, although the electrical properties are hardly affected, the changes of mechanical property and thermal conductivity are big.

2. Beryllium Oxide (BeO)

The thermal conductivity of beryllium oxide is higher than that metal aluminum. If it is used in an occasion with high thermal conductivity, the temperature will drop rapidly after exceeding 300℃. However, beryllium oxide is toxic, which limits its development.

3. Aluminium Nitride (AlN)

Compared with aluminum oxide, aluminum nitride has higher insulation resistance and insulation withstand voltage, and lower dielectric constant. The thermal conductivity of aluminum nitride is 7 to 10 times that of aluminum oxide, and its thermal expansion coefficient is similar to that of silicon wafers, which are very important for high-power semiconductor chips. In the production process, the thermal conductivity of aluminum nitride will affected by the oxygen content. If the oxygen content is reduced, the thermal conductivity can be significantly improved, and the thermal conductivity of the current production level of this process can reach more than 170W/m·k.

HoYoGo is a international, professional and reliable ceramic PCB manufacturer, with many years of experience in ceramic PCB production, it can realize the production of high-tech, high-quality, high-difficulty performance boards, and can guarantee the quality of each product delivered to customers and reliability. We can also provide you with preferential prices for ceramic materials, if you have a demand for making ceramic PCB, please contact us!