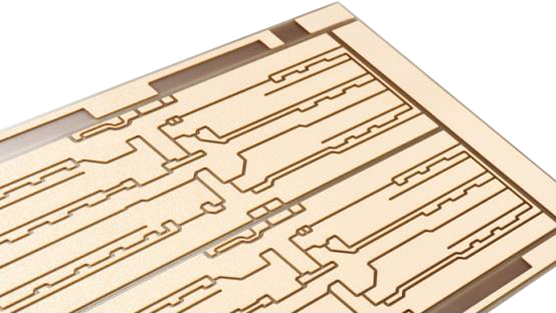

Ceramic PCB is made by bonding the copper foil and the ceramic substrate together in a high temperature environment. Its bonding force is strong, the copper foil will not fall off, and the reliability is high. Its performance is stable under the environment of high temperature and high humidity, so it is widely used in three fields.

1. Automotive electronics industry

Ceramic PCB is very important in improving the overall quality of automotive sensors. The material of the sensor chip is generally silicon, and the thermal expansion coefficient of ceramics and the chip are close, and will not cause too much deformation when the temperature difference changes drastically to cause the circuit to be unsoldered. When a car is running, the internal parts of the car body are in a very harsh environment, and they are often exposed to high temperature and strong corrosion. Ceramic PCB uses inorganic non-conductive ceramic as the base material, and the metal is in direct contact with the ceramic, which has strong corrosion resistance.

2. Communications industry

We are surrounded by all kinds of communication information every day, such as radio, mobile phone, radio communication, navigation, etc., constantly filling our world, and they have become a part of our lives. The reason why they can serve us normally is not only because of modern and advanced network technology, but also because of the important media-antenna.

Antennas are versatile and may be used in a wide variety of environments.The general PCB cannot match its basic performance, and the current high matching degree with it is a ceramic PCB. The antenna in use can generate dangerously high voltages. However, the ceramic PCB has good insulation, which can effectively guarantee personal safety and equipment protection. It can also carry out high-density assembly, so as to realize the short, small, light and thin communication equipment.

3. Aerospace

In the air or in space, the aircraft must withstand ubiquitous forces. The magnitude of the force determines whether the aircraft can operate normally, so a lot of pressure sensors are needed to detect these forces. For example, a series of force sensors such as the engine's intake pressure sensor, exhaust pressure sensor, cabin pressure sensor, and external pressure sensor. Ceramic PCB is better than the general PCB, its stability, reliability, high precision, resistance to cosmic rays, corrosion resistance, etc. fully meet the needs of pressure sensors.

The above is the application of ceramic PCB in three major areas. Ceramic PCB is the direction of market demand, and it is constantly advancing the development of science and technology, and its technology is becoming more and more mature. The future is far more than that, and will be applied to more fields. SHENZHEN HOYOGO ELECTRONIC TECHNOLOGY CO., LTD. is a international, professional and reliable ceramic PCB manufacturer. With our mature technology and high-quality services, we are highly praised and good comments from customers.