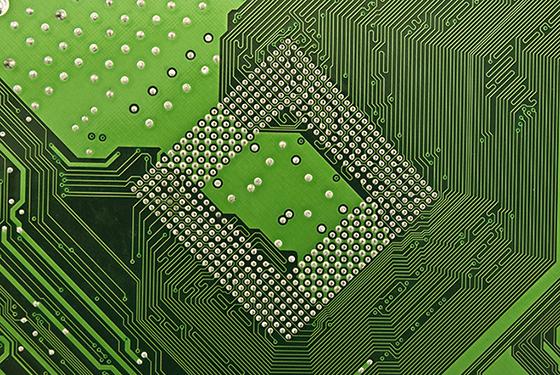

Medical display PCB is a circuit board specially designed for medical display equipment. Its main function is to process and present medical images, including various types, such as X-ray, CT scan and ultrasound. The circuit structure includes an image processing circuit, a display control circuit, an interface circuit and a power management circuit.

Application Scenarios:

Medical display PCB has a wide range of applications in the following medical application scenarios:

1. Medical Imaging Display: It is used in medical imaging equipment such as X-ray, CT scan, MRI and ultrasound, capable of displaying high-resolution medical images to assist doctors in making diagnosis and treatment decisions.

2. Operating Room Monitoring Equipment: The monitoring display used in the operating room can display information such as patient vital signs, surgical progress, and image navigation.

3. Ward Monitoring: This is a monitoring device designed specifically for patients in wards, which can monitor and display patients' vital signs and medical information in real time.

4. Dentistry and Ophthalmology: It is used in dental and ophthalmic imaging equipment to display oral or ocular images.

Product Features

1. High-resolution Display: The design concept of medical display PCB is to pursue excellent high-resolution display function to ensure the clarity and accuracy of medical images.

2. Accurate Color Rendering: Medical images have extremely requirements for color authenticity and accuracy, and medical display PCBs usually have high-level color calibration capabilities to ensure that the color performance of the image is accurate.

3. Real-time Response Time: Medical displays should have real-time response capabilities to ensure immediate display of medical images and vital signs information.

4. Multiple Display: Some medical displays support various display modes, such as single-screen display, picture-in-picture, multi-screen, etc.

5. Protective Design: For the special needs of medical environment, PCB need have protective design to prevent potential risks such as liquid splashing, dust and bacterial contamination.

6. Low Radiation and Low Energy Consumption: Medical display PCB need to adopt low radiation and low energy consumption to meet the safety and environmental protection standards of medical equipment.

7. Remote Control and Monitoring: Some medical display PCB need to have remote control and monitoring functions to facilitate operation and maintenance by medical staff.

8. Data Interface: Medical display PCB usually support multiple data interfaces, such as HDMI, DisplayPort, VGA, etc., to achieve connection with various medical devices.

HoYoGo is an international, professional and reliable PCB manufacturer, we have obtained ISO13485 certification and have consistently implemented the highest industry standards for our production, engineering and procurement teams. We have long time experience and professional technology knowledge in medical PCB assembly. When there is a conflict between Efficiency and PCB's Quality, our priority is always to maintain PCB's Quality. If there is a conflict between Growth Rate and PCB's Quality, we prioritize PCB's Quality over speed.