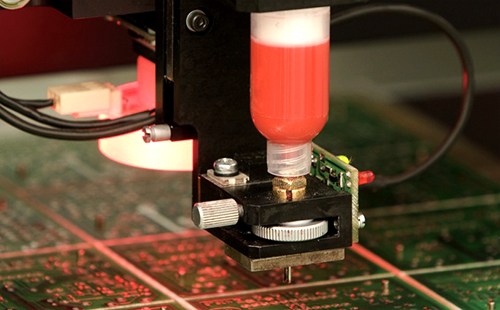

Red Glue is a polyolefin compound and an SMT material. It is different from solder paste in that red glue solidifies when heated. When the freezing point temperature reaches 150℃, the red glue will transform directly from paste to solid. In the SMT patching process, we often see the application of red glue. So what are the significant advantages of red glue?

1. High-precision Attachment: The red glue technology can achieve high-precision positioning and attachment of SMT components, thereby ensuring a stable connection between components and PCB board.

2. Strong Adhesion: Red glue has excellent adhesion properties and can effectively fix SMT components on the PCB board, thus improving the mechanical strength and vibration resistance of the product.

3. High Temperature Resistance: Red glue can maintain stable performance in high temperature environments and is not easy to soften or flow, making it suitable for subsequent welding technologies.

4. Prevent Components from Shifting: During the transfer and reflow soldering process, red glue can play a role in fixing SMT components and prevent the components from shifting or offsetting during the reflow soldering process.

5. Improve Technology Stability: The use of red glue technology can effectively control the positioning and attachment process of SMT components, thus improving the stability and consistency of the production technologies.

6. Improve Production Efficiency: Red glue technology can realize automated production, thereby improving production efficiency, production capacity and reducing production costs.

7. Improve Welding Quality: Red glue has the function of filling the gap between SMT components and PCB boards, thereby reducing bubbles and welding defects during the welding process and further improving welding quality.

8. Reduce Scrap Rate: The use of red glue technology can improve the attachment accuracy and stability of SMT components, thereby reducing the scrap rate caused by component displacement or misalignment.

9. Broad Applicability: Red glue technology is suitable for many types of SMT components, including IC chips, resistors, capacitors, diodes, etc., and has excellent versatility and adaptability.

HoYoGo is an international, professional and reliable PCBA factory. We not only have our own factory, but we also have many years of SMT processing experience. We can provide you with professional SMT processing services, and accept various processing forms such as customers’ materials for processing and OEM.