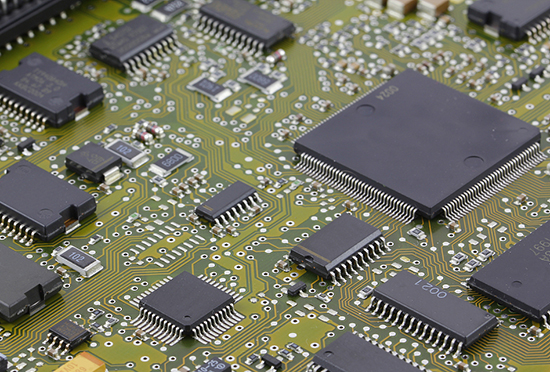

In the SMT processing process, static electricity is a "troublemaker". It will damage our PCB boards and electronic components. What specific problems will it cause? And how do we solve these problem?

Let’s first take a look at some of the problems that static electricity may cause:

1. Component Damage

Electrostatic discharge can cause damage to electronic components. Sensitive integrated circuits, transistors, diodes and other components may suffer from electrical breakdown, excessive voltage and other problems under the influence of electrostatic discharge, and thus lose their normal functions.

2. Production Equipment Failure

Regardless of how small static electricity is, if electrostatic discharge acts directly on production equipment, especially the sensitive electronic components on SMT equipment, it may cause equipment failure and shutdown accidentally, thus affecting production efficiency.

3. Production Line Stagnation

Electrostatic discharge can cause product production lines to stall. On an SMT production line, if static electricity causes damage to electronic components, production may need to be stopped to replace the affected components, which will increase production costs and extend delivery times.

4. Electrostatic Adsorption

The "troublemaker" of static electricity will not only cause electrostatic adsorption between components, making it difficult to separate them, but the positioning will also become chaotic, seriously affecting the accurate positioning and accuracy of SMT equipment.

5. Quality Issues

Electrostatic discharge can cause damage to components in a product, causing quality issues. Damaged components may malfunction after the product leaves the factory, affecting the reliability and service life of the product.

We have learned about some of the problems that static electricity may cause. Next, let’s learn how to skillfully deal with the problems caused by the “troublemaker” of static electricity. In order to reduce the impact of static electricity on SMT chip processing, manufacturers will also take some measures. Let us take a look at how they do it.

1. Use Anti-static Equipment

On the SMT production line, we need to use some professional anti-static equipment. For example: anti-static workbench, anti-static clothing, conductive floor mats, etc., which can reduce the generation and conduction of static electricity.

2. Reasonable Working Environment

Keeping the humidity and temperature of the production environment within a suitable range can effectively reduce the occurrence of static electricity.

3. Use Anti-static Packaging

When storing and transporting components, please don't forget to use anti-static packaging, which can reduce the impact of static electricity on the components during the process.

4. Electrostatic Discharge Test

Conduct electrostatic discharge tests on key equipment and components during the production process to ensure that their antistatic performance meets requirements.

By taking the above measures, the harm of static electricity to the SMT production process can be effectively reduced. In addition, moisture in components will also affect SMT processing. Therefore, appropriate protective measures should be taken when storing electronic components to keep them dry.

HoYoGo is a professional, reliable PCB manufacturer. We can provide one-stop services from upstream electronic component procurement to PCB production and processing, SMT patching, PCBA testing, finished product assembly, etc. All our products strictly follow the acceptance standards of IPC-A-600-H and IPC-6012, and we will never relax any step of testing to ensure good quality for customers, so that customers can buy with confidence and use with peace of mind!