SPI, the full name is Solder Paste Inspection. This is a quality control method used during SMT placement processing. So do you know what role SPI plays in the SMT placement processing?

1. Check SMD Quality

SPI is used to check and verify the quality of the solder paste attached to the circuit board. The solder paste is printed on the component pad on the surface of the circuit board through a stencil during the SMT placement process, so SPI can ensure the uniformity, proper amount and precise position of the solder paste.

2. Avoid Defects

The SPI system can detect parameters such as solder paste thickness, position and shape, thereby helping to prevent soldering defects such as insufficient solder paste, excessive solder paste, offset solder paste and other problems.

3. Improve Manufacturing Efficiency

By monitoring the quality of solder paste in real time, SPI can reduce failures caused by poor solder paste in subsequent manufacturing processes, thereby improving production efficiency. It can also provides rapid feedback so problems can be identified and corrected promptly.

4. Automated Detection

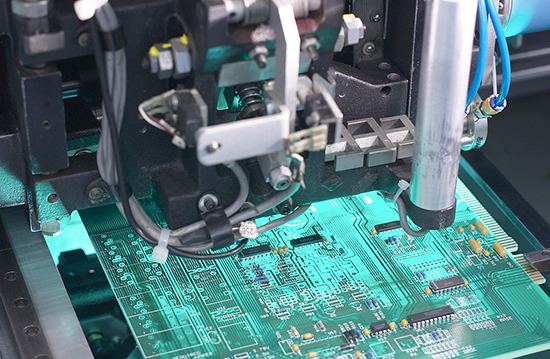

SPI systems are usually automated and can inspect the entire circuit board for solder paste attachment in a very short period of time. Compared with manual inspection, SPI greatly improves the speed and accuracy of inspection.

5. Data Recording and Analysis

SPI systems can usually record detected data and generate reports. SPI systems are usually able to log detected data and generate reports. This data can be used for quality control, process improvement and product traceability. By analyzing this data, manufacturers can adjust production processes in a timely manner and improve product quality.

To sum up, the role of SPI in the SMT placement processing is to ensure the quality of solder paste, prevent welding defects, improve manufacturing efficiency, and provide key data support for the optimization of the production process. The SPI system is usually one of the important links in the SMT production line and is crucial to ensuring the quality of circuit board welding.

HoYoGo is an international, professional and reliable PCB manufacturer. We not only have our own factory, but also have many years of experience in SMT processing. We can provide you with professional SMT processing services, and accept various processing forms such as customers’ material for processing and OEM.