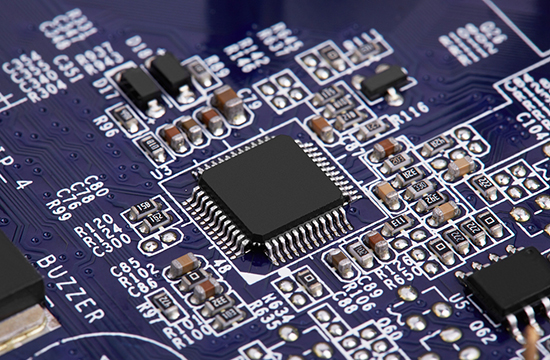

In PCBA factories, the selection of equipment plays a vital role in ensuring the quality of PCBA. Correct selection and use of equipment can improve production efficiency, reduce defective rates, and ultimately provide customers with high-quality products. Do you know what equipment can ensure the quality of PCBA?

1. SMT Machine

SMT machine is the one of the most important equipment. Its main function is to pick up components from one location and place them accurately on the PCB board. The accuracy and stability of the SMT machine are crucial to the quality of PCBA. High-precision SMT machines can accurately place components at designated locations to avoid errors and error accumulation. SMT machines with higher stability can maintain accuracy during high-speed production and improve production efficiency. Therefore, when selecting a SMT machine, factors such as accuracy, stability, and production speed need to be considered to meet customer requirements for PCBA quality.

2. Reflow Oven

A reflow oven is a device that melts and solidifies solder paste onto the PCB. The quality of welding directly affects the reliability and stability of PCBA products. The temperature and heating control capabilities of the reflow oven play a key role in soldering quality. Proper temperature control ensures that the solder melts fully and makes a good connection with components and PCB. High-precision heating control can avoid welding overheating or overcooling, thereby reducing the occurrence of welding defects. Therefore, when selecting a reflow oven, factors such as heating control capability and temperature stability need to be considered to ensure welding quality and PCBA quality.

3. SMT Testing Equipment

SMT testing equipment is the key equipment used to detect the quality of SMT welding. It can detect parameters such as the position of solder joints, the coating of pads and the correctness of placement. SMT testing equipment can help engineers discover and correct welding defects in time to avoid the production of defective products. Common SMT testing equipment includes X-ray inspection machines, AOI equipment, etc. These equipment can provide high-precision detection capabilities, greatly reduce the defect rate of PCBA products and ensure the quality of PCBA.

4. Electrostatic Protection Equipment

Static electricity is a huge threat to components and equipment in the PCBA manufacturing process. The accumulation and release of static electricity may cause component damage or failure, affecting the quality of PCBA. In order to protect components and equipment from the effects of static electricity, PCBA factories need to be equipped with certain electrostatic protection equipment. These equipment include static protective clothing, static eliminators, static floors, etc. Electrostatic protection equipment can effectively control and eliminate static electricity to ensure the stability and quality of the PCBA manufacturing process.

To sum up, the selection of equipment in the PCBA factory is crucial to ensuring the quality of PCBA. SMT machines, reflow ovens, SMT testing equipment and electrostatic protection equipment are several key factors that affect the quality of PCBA. When selecting these equipment, it is necessary to consider their characteristics such as accuracy, stability, and control capabilities to meet customer demand for high-quality PCBA products.

HoYoGo is an international, professional, top 15 PCBA manufacturer in China. We have our own factory production bases, advanced machines, and experienced technicians and multiple quality control personnel to strictly control every quality inspection, which can ensure the reliability of the quality of every product delivered to customers. If you have relevant needs, welcome to contact us!