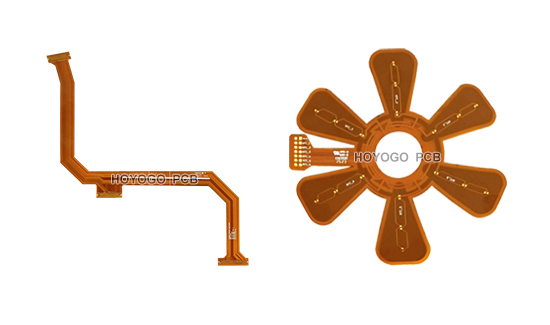

FPC has the advantages of thin, light, and flexible, and can be flexibly routed in complex or restricted spaces. During the production of FPC factory, coverlay are sometimes opened on the FPC. What is FPC coverlay opening? Why does FPC need to open coverlay?

1. What is FPC Coverlay Opening

FPC coverlay opening refer to coating a protective film on the FPC, and then opening the film layer through cutting or etching technology to expose part of the circuit that needs to be exposed. This can protect the FPC while ensuring that the required circuits can work properly.

2. Why dose FPC need to Open Coverlay

1) Circuit connection

FPC is often used to connect different parts of electronic devices or systems. The coverlay openning process exposes the circuitry beneath the coverlay for physical and electrical connections to other circuits, components or connectors. Coverlay opening provides more direct access to circuits and enables efficient connections of circuits.

2) Soldering and Metallization

In the manufacturing of FPC, it is often necessary to weld or metallize the circuit to achieve circuit connection and signal transmission. The coverlay opening process can leave a pad or metallization area on the coverlay, so that the welding or metallization technology can be performed better, and the quality and reliability of the welding or metallization can be improved.

3) Testing and Detection

The coverlay opening process can open test points on the coverlay to facilitate testing and inspection of the circuit. Testing and inspection are important links in the FPC manufacturing process. By opening coverlay, you can easily access and measure the signal transmission and performance of the circuit, improving the control of the manufacturing process and ensuring product quality.

4) Thickness Control

FPC is usually made of multilayers of thin film materials, including base materials, copper foil, etc. Coverlay opening can create areas of varying thickness on the coverlay to meet the needs of specific sections. The local thickness of the FPC can be controlled through windowing to adapt to different connectors and assembly requirements.

5) Flexibility and Bendability

Coverlay opening can reduce the coverage of the coverlay in the circuit area, thereby reducing the thickness of the coverlay and increasing the flexibility and bendability of the FPC. As a flexible circuit board, one of the main characteristics of FPC is its high flexibility and bendability. These characteristics can be further enhanced through coverlay opening.

HoYoGo is an international, professional and top 15 FPC factory in China. Our production strictly follows a high quality system and has passed ISO9001, ISO14001, ISO13485 and TS16949 and C-UL-S certifications. All products strictly follow the acceptance standards of IPC-A-600-H and IPC-6012. The quality of our products has been widely recognized by customers in European and American countries. If you have related needs, you are welcome to send us an inquiry.