PCB is one of the essential components of electronic products, and its quality directly affects the performance of the entire product. In order to protect the PCB and ensure the reliability of the product, the PCB manufacturer will pack the PCB. So what are the requirements for PCB packaging?

1. Anti-static

Because static electricity will interfere or damage the circuit, anti-static measures need to be taken during the PCB packaging process. For example: PCB manufacturers will package PCBs in conductive layers or static shielding bags, or use packaging equipment with static elimination devices, etc.

2. Waterproof and Moisture-proof

PCB are sometimes affected by humid environments, especially during transportation and storage. Therefore, during the PCB packaging process, it is necessary to pay attention to waterproof and moisture-proof. For example: PCB manufacturers will choose packaging materials with good airtightness, and add hygroscopic agents, moisture-proof agents, etc., to ensure the quality of PCB.

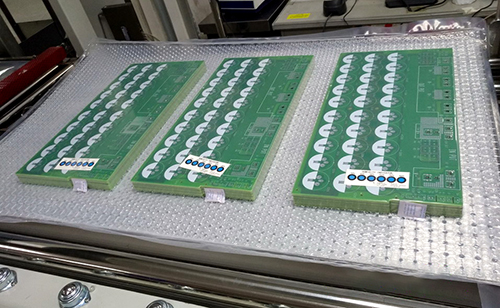

3. Shockproof and Anti-pressure

In order to ensure that the PCB is not affected by mechanical shock and extrusion during transportation, it is necessary to use fillers with cushioning properties. For example: PCB manufacturers will use air column bags, film plastics, film paper, etc. These packaging materials can well reduce the mechanical impact of PCB, so as to ensure the quality of PCB.

4. Clear Identification

In the process of PCB manufacturing and use, it is easy to confuse or misuse circuit boards of different models and functions. Therefore, in the PCB packaging process, it needs to be clearly marked, including information such as model, batch, and production date. This can facilitate the user to use and maintain the PCB.

5. Perfect Management

In the process of PCB manufacturing and use, comprehensive management and supervision are required to ensure that the packaging of PCB meets the requirements to ensure product quality. Establish corresponding PCB packaging standards and processes, and strictly manage and supervise the manufacturing, transportation and storage processes.

HoYoGo is an international, professional and reliable PCB manufacturer, we adopt suitable packing methods and fillers to ensure the safety and stability of PCB during transportation. We also pay attention to labeling requirements and environmental protection requirements to ensure that the PCB packaging of each batch of shipments meets the standards. We strictly control every quality pass, so that every customer can feel the best quality service.