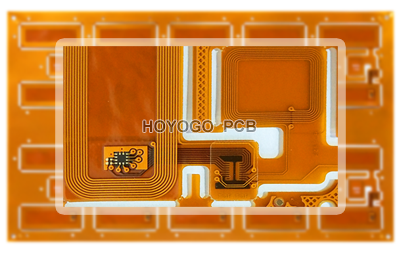

FPC is a thin, light, flexible circuit board, which is widely used in electronic devices such as mobile phone, laptop and cameras, etc. However, FPC manufacturers sometimes have defective boards in the production process, so what cause the defect? How to solve these defect?

1. FPC hole have solder mask and patterns have pinholes

Main Reason:

1) FPC did not print paper in time during screen printing, resulting in too much residual ink accumulated on the screen plate, and then the residual ink would be printed into the hole under the pressure of the scraper.

2) If the screen mesh number is too low, it will also cause solder mask in the hole.

3) There is dirt on the photographic plate, which will cause the part of the FPC that should be exposed during the exposure process to lose light, resulting in pinholes in the patterns.

Solution:

1) The paper should be printed in time and the high-mesh screen plate should be selected.

2) During the exposure process, the cleanliness of the photographic plate should be checked frequently.

2. The FPC copper foil line has blackening phenomenon

Main Reason:

1) The FPC is not dried after wiping the board.

2) Before printing the solder mask, the surface of the FPC is splashed with liquid or molded by hand.

Solution: Visually inspect the copper foil on both sides of the FPC for oxidation during screen printing.

3. Dirt and unevenness on FPC surface

Main Reason:

1) Dirt on the surface is caused by flying hair and other debris in the air.

2) The uneven surface is caused by not printing paper and cleaning the residual ink of the screen in time during screen printing.

Solution:

1) When cleaning the workshop, the cleanliness of the operator should be fully guaranteed, and irrelevant personnel should be prevented from passing through the clean workshop, and the clean workshop should be cleaned on time.

2) When screen printing, the residual ink on the screen should be cleaned up in time.

4. FPC has ghosting and cracking phenomenon

Main reason:

1) Ghosting is due to the poor positioning of the FPC board during screen printing and the residual ink on the screen is not removed and accumulated on the board in time, resulting in regular ink spots next to the entire FPC pad.

2) Cracks are due to insufficient exposure during the FPC exposure process, resulting in small cracks on the board surface.

Solution:

1) Fix it firmly with positioning pins, and remove the residual ink on the screen in time with the printing paper;

2) Measure the exposure, so that the comprehensive value of the exposure lamp energy, exposure time and other parameters reaches between 9-11 exposure levels, and cracks will not appear within this range.

5. Inconsistent colors on both sides of FPC and skip printing problems

Main Reason:

1) The number of knives for screen printing on both sides is very different, resulting in inconsistent colors on both sides of the FPC.

2) Mixing of old and new inks: It is possible that one side is using new ink that has been stirred, while the other side is using old ink that has been placed for a long time.

3) Skip printing is due to the excessive electroplating current and thick coating, resulting in too high pattern lines.

4) When screen printing FPC, the scraper and the screen printing frame form a certain angle for screen printing, and the printing will skip on both sides of the line because the line is too high and the ink is not poured. Another reason is that there is a gap in the scraper, and the gap does not contain ink, resulting in skipping printing.

Solution:

1) Try to keep the number of screen printing knives consistent.

2) Avoid mixing old and new inks.

3) Pay attention to control the plating current.

4) Check whether there is a gap in the scraper.

HoYoGo is an international, reliable FPC manufacturer, including one-stop services from upstream electronic component procurement to FPC production and processing, SMT placement, FPC testing, and finished product assembly. All of our products strictly follow the acceptance standard of IPC-A-600-H and IPC-6012. We do not relax any step of inspection, guarantee the quality for customers, and let customers feel at ease!