If the PCB adopts reflow soldering process, then the solder needs to be applied to the soldering part before soldering. The main methods of applying solder to solder parts are the solder paste method, the pre-solder method, and the pre-formed solder method.

1. Solder Paste Method

Applying solder paste evenly to the PCB pad pattern is the most commonly used method in the reflow soldering process. The purpose is to ensure that the pads corresponding to the SMT components and the PCB achieve good electrical connection during reflow soldering, and have sufficient mechanical strength. There are two methods to apply solder paste: Injection drop coating method and printing coating method. The injection drop coating method is mainly used in the development of new products or the production of small batches of products, and can be operated manually. Although the speed is slow and the precision is low, it has high flexibility and saves the cost of manufacturing templates.

2. Pre-solder Method

The pre-soldering method is also a method of applying solder that is often used in the reflow soldering process. In some applications, electroplating and melting methods can be used. The solder is pre-applied on the fine leads of the electrode part of the component or on the pad of the PCB. In the assembly of narrow-pitch devices, it is more appropriate to pre-apply the solder by electroplating. However, the thickness of the solder plating layer of the electroplating method is not stable enough, and it needs to be melted again after the solder is electroplated. After such treatment, a stable solder layer can be obtained.

3. Pre-formed Solder Method

Peformed solder is preformed solder made of solder into various shapes, such as sheets, rods, tiny balls, etc. The solder may contain flux. This form of solder is mainly used in bonding parts in semiconductor chips, and in the welding process of flat package devices.

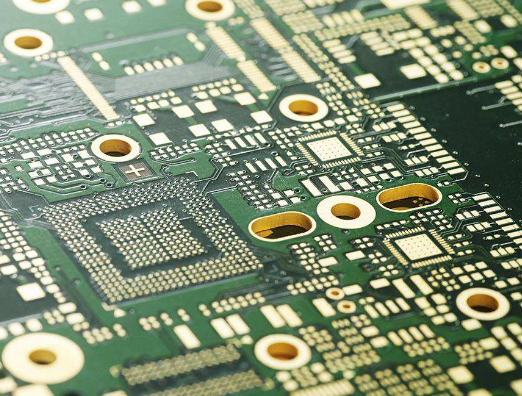

HoYoGo is an international, professional and reliable PCB manufacturer with many years of PCB production experience, which can realize the production of high-tech, high-quality, high-difficulty performance boards, and can guarantee the quality and reliability of each product delivered to customers. We can also provide you with preferential prices, if you need to make PCB, welcome to contact us!