In PCBA processing, it is more common to apply solder paste for soldering by wave soldering or reflow soldering, but sometimes a dispensing technology is also required. So what is the use of the PCB dispensing technology?

1. Underfill

While the miniaturization of chips in electronic product is becoming more and more popular, miniaturization also brings solder joint reliability issues. Although the components and substrates are soldered with solder paste, due to the small size, the solder joints are more prone to stress and fall off, so the underfill technology is introduced. In this technology, underfill is applied to one side of the solder joints by dispensing, and all solder joints are filled under capillary action. Underfill can also effectively reduce the problem of uneven stress and solder joint failure caused by mismatched thermal expansion coefficients. Underfills are used widely in electronic packaging.

2. Making Solder Joints

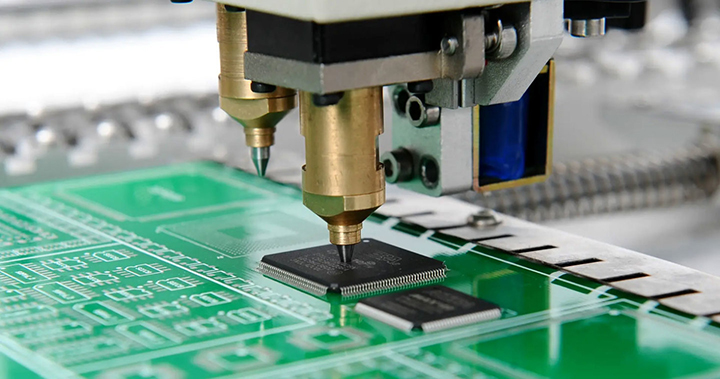

Similar to printing techniques, the dispensing technology is also widely used to create solder joints on pads. Solder paste is usually contained in a syringe and released onto the pad under pressure from the dispensing machine. The dispensing technology is different from printing. The dispensing is non-contact and does not require the use of a stencil. Dispensing machines can be divided into two types: semi-automatic and fully automatic. The glue output and glue time parameters of the automatic dispensing machine are more adjustable, which can better meet the large-scale dispensing technology. There are a variety of dispensing systems available today, including pneumatic, jet, quantitative, and screw types.

HoYoGo is an international, professional and reliable PCB manufacturer, with our own production capability, we can provide you with one-stop service from small, medium to high volume production. We can provide HDI PCB, gold finger PCB, hard gold PCB, flexible PCB, rigid-flex PCB, metal base PCB, quick turn PCB and PCBA.