The PCB break away tab is not part of the PCB, and its existence will consume more boards, thereby increasing the cost of the board, so we need to remove it after the PCBA processing is completed. But even so, the PCB still needs to retain the existence of the break away tab during production, which shows its importance. So what is the role of the PCB break away tab?

During the SMT placement process, the PCB board is conveyed through the guide rails of the machine. If the break away tab is not reserved, there will be a phenomenon that the component is too close to the edge of the PCB board when mounting, and when the component is beyond the scope of the PCB board, it will not be possible to mount and solder normally. Therefore, the function of the break away tab is to expand the distance between the components and the equipment to assist the board routing and ensure the normal operation of the SMT placement process.

The flatness of the PCB break away tab is also a part that needs to be controlled in PCB production. When removing the PCB production break away tab, it is necessary to ensure the smoothness of the break away tab, especially for PCB boards that require high assembly accuracy. Any uneven burrs will cause the mounting holes to be offset, which will bring inconvenience to the subsequent PCBA assembly and processing, and the method of removing the break away tab is the same as that of the PCB splitting.

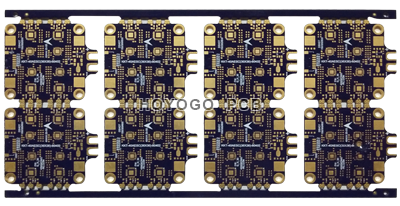

HoYoGo is an international, professional and reliable PCB manufacturer with 2 PCB factory production bases, our production strictly follows the high quality system and has passed ISO9001, ISO14001, ISO13485 and TS16949 and C-UL-S certification.